But I got to see a lot of great places, meet very interesting people, and help solve many problems with Autodesk software. During my travels, I've delivered more hours of training, support, demos, and implementations that can remember. I spent the first decade of my career working for an Autodesk reseller as an Application Specialist. Hello! My name is Mike Thomas and I have a lot of experience with Autodesk products, primarily in the Manufacturing realm. Next time, I’ll dive in and attempt to set up an associative relationship between Inventor and a Fusion design. It works well for tossing the part over the fence, for use in the other application. Use this workflow when you are not intending for the data to come back. Constrain only what you are changing or need to move. As the components are located in the correct location, ground them to prevent them from inadvertently moving. In addition, add features to your heart’s content.Īssembly component relationships are the real downer, although more importantly missing within Inventor. If the model changes in either application you’ll need to re-import/re-export.įeatures do not translate, however, you can tweak the models once opened in the other application. It is important to remember that the data is non-associative. Fusion exports data into the Inventor format, again meaning no third-part-neutral-intermediate. Fusion 360 opens Inventor natively, without the need for translation or export. Hopefully, you can see how easy it is to exchange data between the two systems. Therefore any feature added after will be captured in the timeline.

You can (via the browser) enable Capture Design History. Also, there is no limitation in adding features.īy default, capturing design history is disabled. Multiple Solid Bodies Imported into FusionĮven without the features (history), you can use the editing tools, like Press Pull, to make adjustments to the model. This is good as the flow between bodies and components within Fusion 360 kicks butt. Inventor Part vs Imported Fusion Designįusion 360, however, will import a multi solid body Inventor part file as a multi-body design. The result is similar to what occurs when modeling within Fusion with History turned off.

Even though the Inventor model is fully featured, it imports as a single bodied part with no features. Partsįusion treats an Inventor part as it would other 3rd part files (like STEP).

Autodesk fusion 360 vs inventor update#

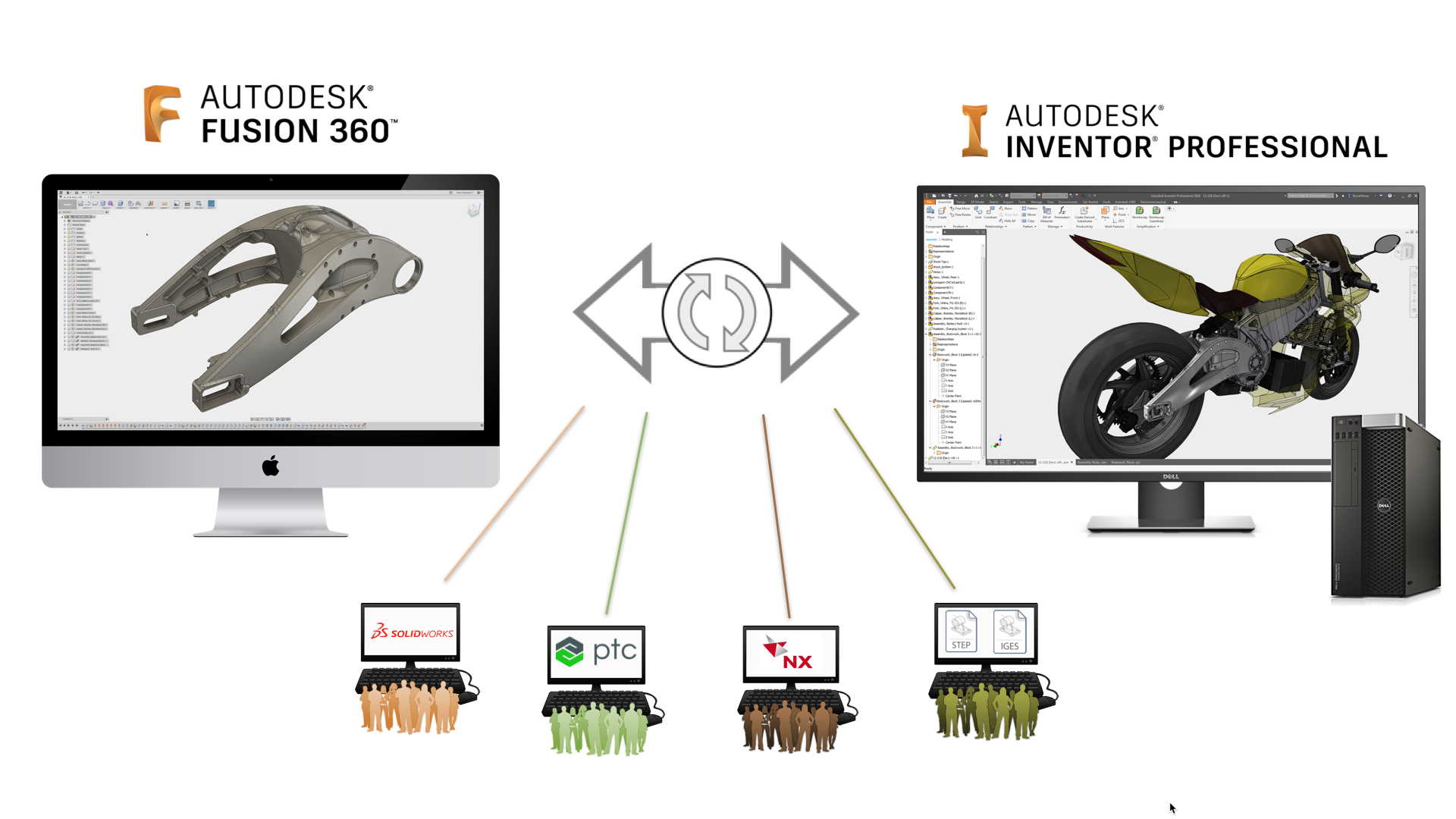

The imported model is NOT associative to the original, meaning changes within Inventor will NOT update the model within Fusion 360. After selecting the file the upload process begins, which you can dismiss and allow to complete in the background. Inventor to Fusion 360įusion 360 offers the ability to open Inventor parts (IPT) and assemblies (IAM) directly. So as Inventor and Fusion are in the same family, it would be appropriate that they can read each other’s files? Right? Put on top of this Inventor’s An圜AD and Fusion 360’s openness to data and it seems like the start of a beautiful relationship. This comparison makes sense as Fusion is the new kid on the block, shares many similarities to Inventor, and they are both in the same Autodesk manufacturing family. Paul Munford once described Fusion 360 as Inventor’s little brother. And not only with 3 rd party formats, Inventor talks with AutoCAD, Revit, Fusion 360, and other products within the Autodesk family. An圜AD is Inventor`s ability to work with and exchange data from a variety of sources.

0 kommentar(er)

0 kommentar(er)